Do you need a financi Read more [...]

Lochaber Graphite Project (Canada)

Project Category: Exploration

-

Great Lakes Graphite Inc. is seeking indicative offers for its 100% interest in the Lochaber Graphite Project, Quebec, Canada.

Project highlights include:

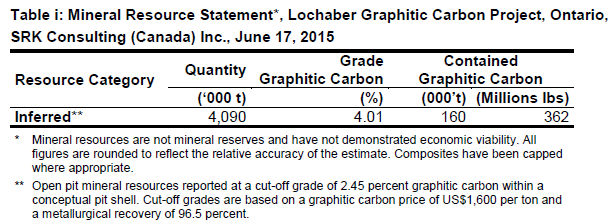

Mineral Resource of 4Mt at 4% graphite (2015 NI 43-101 Report).

Particle size distribution test results: over 57% large flake, including 44% jumbo flake.

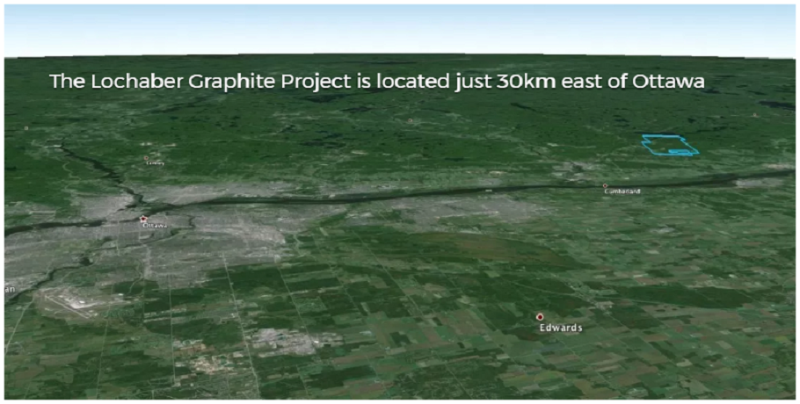

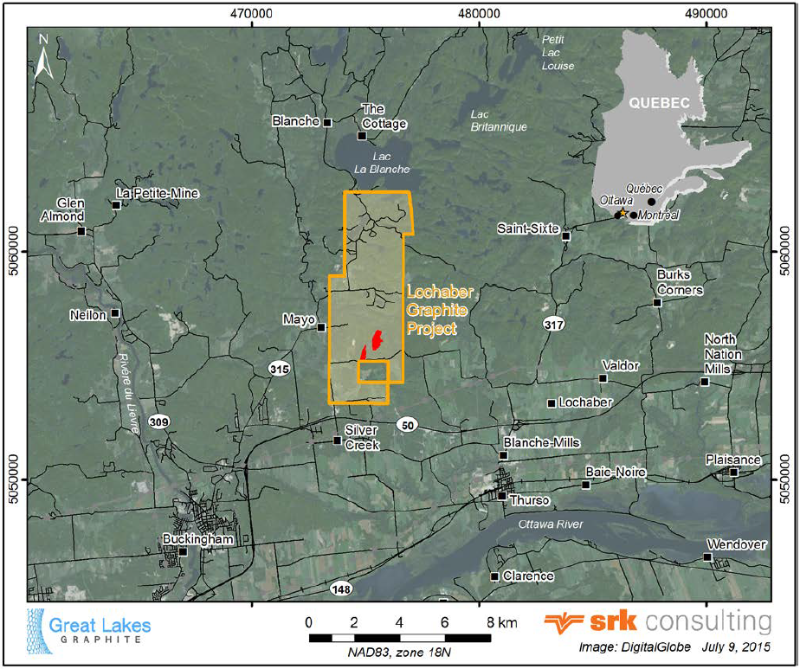

Close proximity to infrastructure (30km east of Ottawa) will facilitate future development.

Excellent exploration potential to expand upon the existing resources.

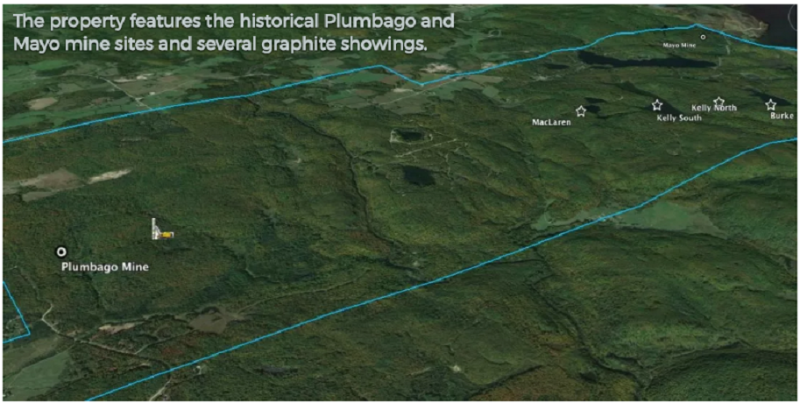

Some of the oldest graphite showings in Canada including two historic mines (Plumbago produced 545t between 1864 and 1868).Primary Contact Person: Brett Clark

Company Name: Doonbeg Group

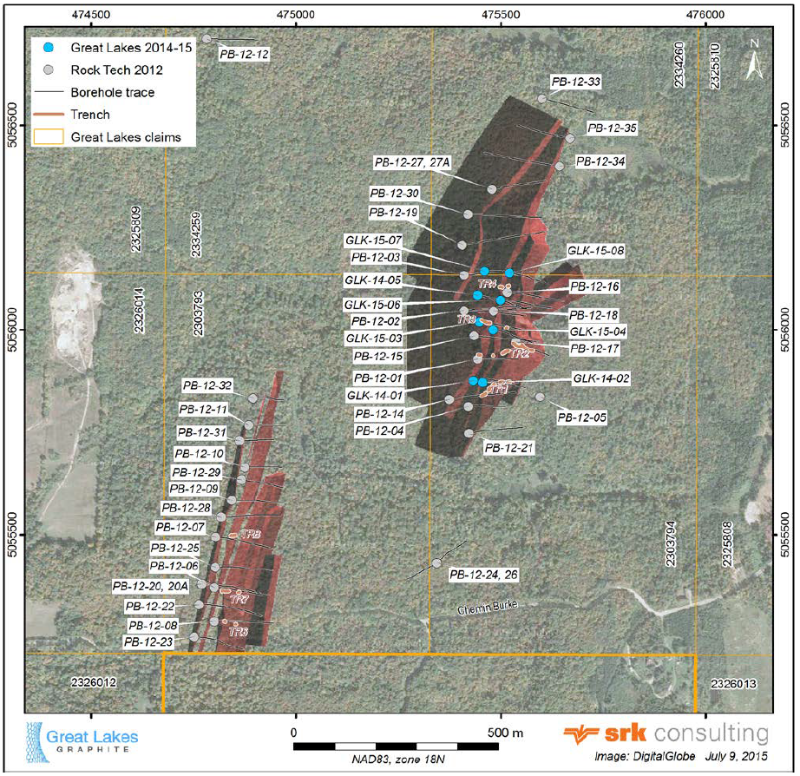

Telephone Number: +1 646 249 4077 / +61 408 941 557Great Lakes and Rock Tech have carried out exploration on the Lochaber graphite project since 2012. Exploration in 2012 was conducted by Rock Tech and consisted of prospecting, grab sampling, ground geophysical surveys, and core drilling in the Plumbago area. Exploration in 2014 – 2015 was conducted by Great Lakes to follow up on the Rock Tech results with additional core drilling in the Plumbago area and an airborne drone elevation survey.

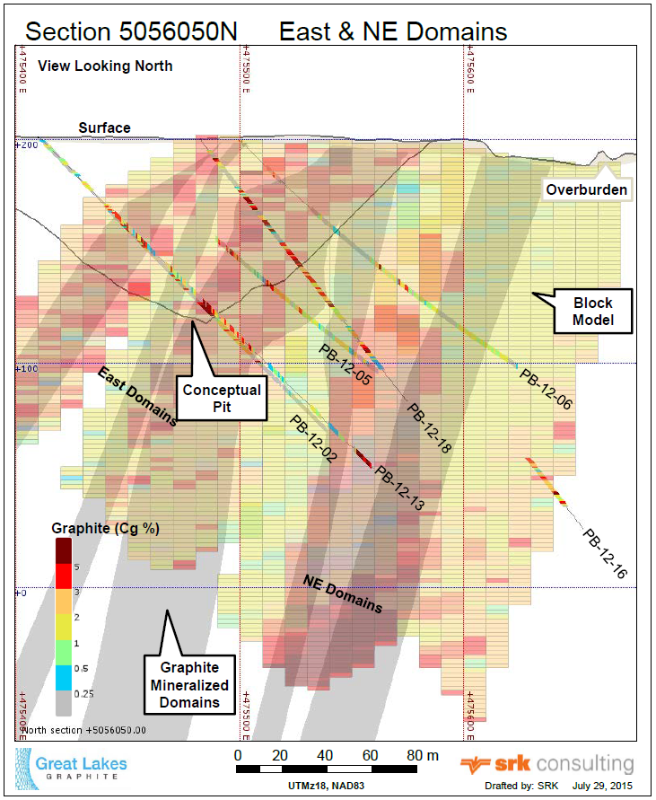

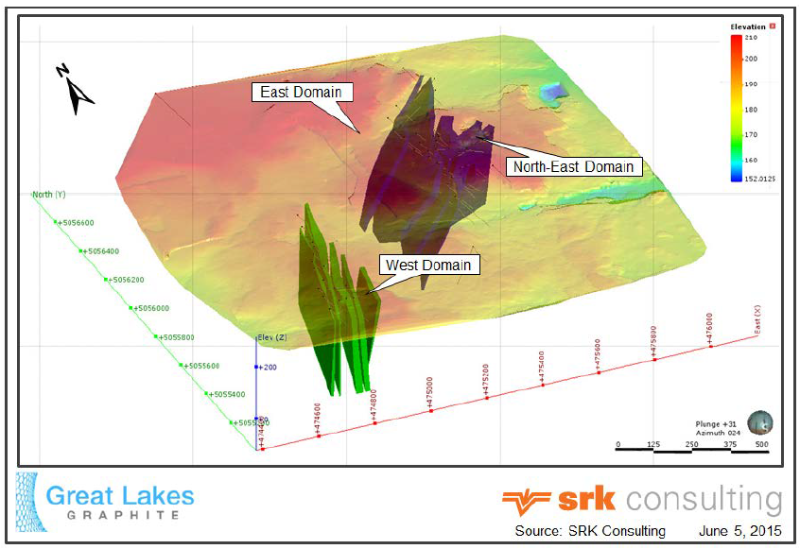

Between 2012 and 2015, Great Lakes and Rock Tech have drilled a combined 45 core boreholes (8,110 metres). In addition, Rock Tech completed seven trenches with 19 sampling channels (357 metres of channel sampling). The 2015 mineral resource evaluation considers both the drilling and trenching sampling data

A maiden resource estimate was completed in 2015, showing 4Mt (inferred) at 4% graphite, based on 7,000+ metres of drilling by the previous operator and 1,200 metres drilled in Great Lakes’ 2014/15 program.

Mineral Resource

Particle size distribution test results: over 57% large flake, including 44% jumbo flake.

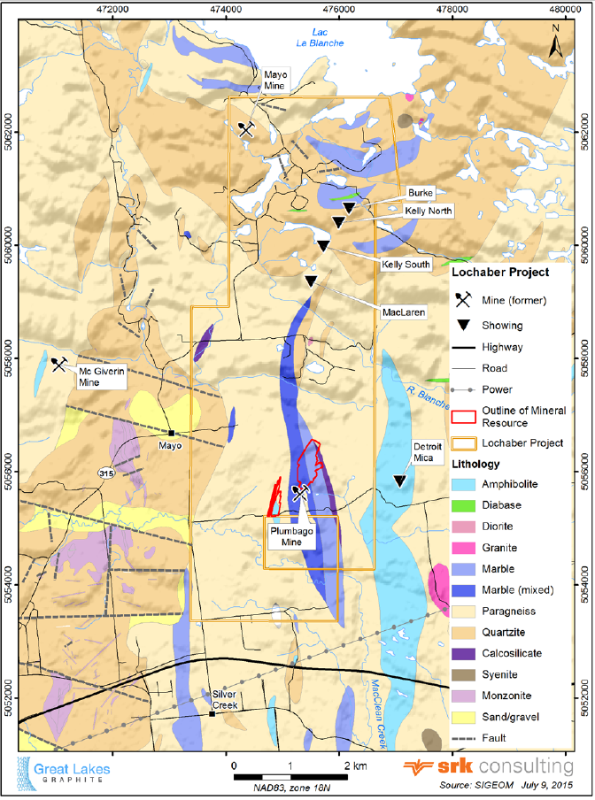

Purity: +95%The Lochaber Graphite Property is comprised of 45 mineral claims, in one contiguous block, covering 2,649 hectares in the Buckingham area on NTS maps 31G11. The property is located in the municipality of Mayo (Lochaber Township), east of the town of Buckingham, but is part of the MRC (La municipalité régionale de comté) of Papineau, Province of Quebec, Canada.

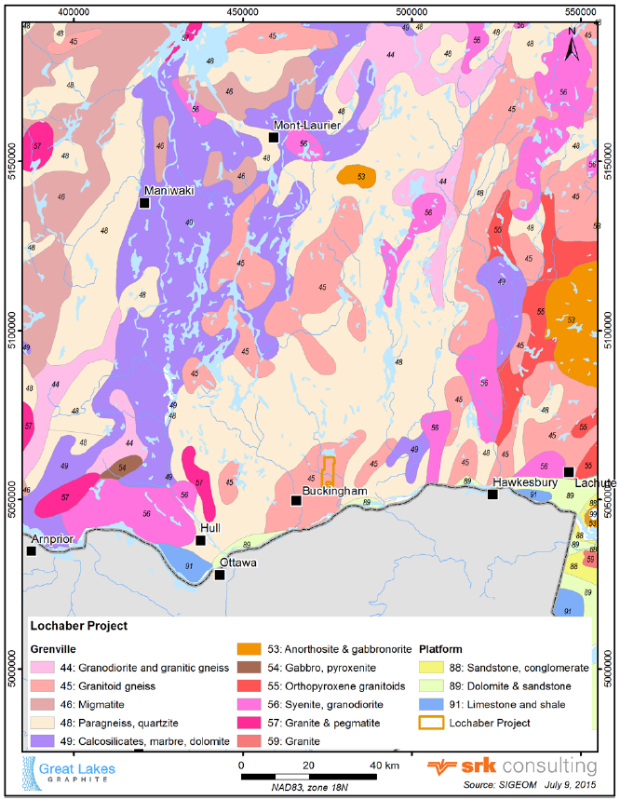

The Lochaber graphite project is located in the Central Metasedimentary Belt of the Mesoproterozoic age (1.6 Ga – 1.0 Ga) Grenville Structural Province of the Canadian Shield. The Central Metasedimentary Belt comprises north-northeast-trending marble and quartzite domains or terrains that also include quartzo-feldspathic gneisses and (meta) tonalite intrusions.

Regional metamorphism is of upper amphibolite grade and, locally, granulite facies. Suites of north-trending monzonitic, dioritic, and gabbroic rocks are present along the boundaries of the Central Metasedimentary Belt.

The Lochaber graphite project is underlain by quartzofeldspathic, garnetiferous paragneiss, and limestone / marble beds.

Graphite is a soft, crystalline form of carbon under standard conditions and can be considered the highest grade of coal, though it is not normally used as fuel because it is difficult to ignite. It is gray to black, opaque, and has a metallic lustre. Graphite occurs naturally in metamorphic rocks such as marble, schist, and gneiss. It can also be found in veins and pegmatites.

Graphite mineralization on the property is associated with gneissic rocks in contact with limestone / marble in a shear zone. Regional strike of the rocks is north-south while the shear zone at Plumbago mine pit has a strike 045 degrees and dip of 70 degrees to the northwest. Other controls of mineralization apparent in the trenches are the presence of diabase dikes and pegmatitic textures in the marble and paragneiss. Graphite occurs as crystalline large flaky texture with a shiny metallic luster; flake size ranging from 1 to 3 millimetres and sometimes up to 5 millimetres. The distribution of graphite is irregular and mostly occurs as fracture filling or pockets and along gneissic banding. The Plumbago mine showing was discovered in 1864 and stopped producing graphite in 1868 with an estimated production of 545 tonnes of graphite. The graphite mineralization is in the form of coarse flake graphite within sheared paragneiss rocks.

The current mineral resources occupys only a small footprint within the Lochaber property and the graphite mineralized zones in the Plumbago area are open to the north along the main graphite mineralization trend identified by Great Lakes. Exploration outside of the extents of the current modelled mineralization is to be considered. These could be tested by trenching and channel sampling.

The Lochaber property has a historical record of graphite exploration and production. Flake graphite occurrences on the property are some of the oldest graphite showings in Canada, having been discovered in the late 1800s and early 1900s when there was a considerable interest in graphite due to its properties as a lubricant. There are three historical graphite occurrences (the McLaren, Kelly, and Burke showings) and two past producing graphite mines (the Mayo and Plumbago mines) on the property. The mineral resource is in the Plumbago mine area.

Metallurgical Testwork

Bench scale scoping tests examining physical beneficiation techniques (grinding followed by either gravity or flotation) on composite core samples and samples collected from the waste piles of the Plumbago mine site area were performed. The testing performed by Rock Tech (2012) indicates the graphite flake recovered from the composite core sample is of high grade (+97 percent) through the different sizes. Testing performed by ORTECH (Great Lakes – 2014) has indicated that flotation upgrading of the material achieves a graphite grade of 93.4 percent to 96.5 percent recovery. These results indicate that the graphite bearing material is amenable to physical upgrading techniques and more detailed studies will improve recoveries along with retaining flake integrity.

-

Total Resource Estimate (M+I+I): 4Mt (inferred) at 4% graphite

-

-

Key Documents: 2015-NI-43-101-Resource-Estimate-Lochaber-SRK.pdf